Prevent Stun Gun Misfires: Advanced Features for Security Batons

Heavy-duty stun batons for security professionals integrate advanced safety features and reliable te…….

Heavy-duty stun batons for security professionals integrate advanced safety features and reliable technology to prevent misfires and ensure effectiveness in critical situations. Crafted from robust materials, these batons boast high-voltage, low-current electrical pulses, impact-activated triggers, automatic shut-off mechanisms, and smart sensors monitoring battery voltage, current draw, and temperature. Regular maintenance, including cleaning, lubrication, and adherence to storage guidelines, is vital for optimal performance and safety. Choosing equipment with these advanced features prioritizes user well-being and security professionals' effectiveness in high-pressure scenarios.

In the realm of personal security, heavy-duty stun batons have emerged as powerful tools. However, ensuring their optimal performance is paramount to prevent accidents and misfires. This article delves into the critical aspects of stun gun misfire prevention, exploring the mechanisms behind these devices and the advanced features designed for safe operation. From understanding common misfire causes to discussing heavy-duty stun batons’ material considerations and the role of advanced sensors, we provide a comprehensive guide on maintaining these security tools to ensure user safety and effectiveness.

- Understanding Stun Gun Mechanism and Common Misfires

- Heavy-Duty Stun Batons: Design and Material Considerations

- Advanced Sensors for Real-Time Performance Monitoring

- Safe Operation Features for User Protection

- Maintenance and Care to Prevent Misfires in Security Equipment

Understanding Stun Gun Mechanism and Common Misfires

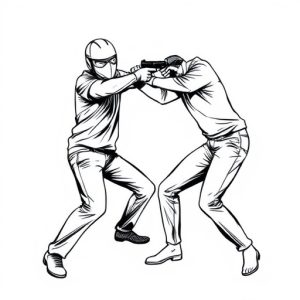

Stun guns, also known as electronic control devices (ECDs), work by delivering a strong electric shock to incapacitate an attacker. The mechanism involves a trigger that activates a high-voltage, low-current electrical pulse, usually through two prongs or probes on the device’s end. This shock disrupts muscle control in the target, causing temporary paralysis and allowing the user to escape or gain control of the situation. However, several factors can contribute to misfires, which can be concerning for users relying on these devices for personal safety, especially when facing dangerous situations.

Common causes of stun gun misfires include poor battery contact, device damage, interference from metal objects or clothing, and improper usage. Heavy-duty stun batons designed for security purposes often incorporate advanced safety features to mitigate these issues. These features may include improved battery contact mechanisms, impact-resistant designs, smart sensors to detect proper application, and automatic shut-off functions to prevent accidental activation. Understanding the mechanism behind stun guns and being aware of potential misfire causes is crucial in choosing reliable heavy-duty stun batons that offer enhanced security for personal protection.

Heavy-Duty Stun Batons: Design and Material Considerations

Heavy-duty stun batons are designed with robust materials to withstand rigorous use, making them a top choice for security professionals. These batons often incorporate advanced design elements that ensure reliability in critical situations. The exterior is typically crafted from high-impact polycarbonate or aluminum, capable of resisting dents and cracks, even under extreme force.

The core component is usually a powerful electric shock mechanism, featuring a high-voltage, low-current stun system. This technology delivers a potent jolt that incapacitates the target without causing permanent harm. The internal wiring and circuit boards are designed to prevent short circuits and misfires, ensuring consistent performance. Additionally, these batons often include safety features like impact-activated triggers and automatic shut-off mechanisms to mitigate accidental deployments.

Advanced Sensors for Real-Time Performance Monitoring

Advanced sensors play a pivotal role in modern heavy-duty stun batons, ensuring their effectiveness and safety. These sensors are designed to monitor real-time performance, providing critical data that helps prevent misfires. By continuously assessing various parameters like battery voltage, current draw, and temperature, the stun gun can detect anomalies that might lead to malfunction.

This proactive monitoring allows for immediate adjustments or warnings, ensuring the user is always aware of the device’s condition. The result is a more reliable tool for security professionals who rely on heavy-duty stun batons in high-pressure situations, where every second counts.

Safe Operation Features for User Protection

Stun guns, also known as electronic control devices (ECDs), are designed to incapacitate an assailant temporarily with a powerful electrical shock. However, ensuring safe operation is paramount to prevent accidental misfires and protect users. Many modern stun guns incorporate advanced safety features for user protection, especially in the case of heavy-duty stun batons for security professionals. These include sensitive activation mechanisms that require firm pressure to avoid unintended deployment, ensuring the user’s control over the device.

Additionally, smart circuit designs prevent overloading and short circuits, which can lead to misfires or device damage. Some models even feature automatic shutdown mechanisms after a certain period of continuous use to safeguard against excessive energy discharge. These safety measures are crucial for professionals who rely on stun batons as a last line of defense, emphasizing the importance of choosing equipment with robust safety features to ensure their well-being and effectiveness in high-pressure situations.

Maintenance and Care to Prevent Misfires in Security Equipment

Regular maintenance and care are essential to prevent misfires in heavy-duty stun batons for security equipment. Users should clean the device after each use, removing any debris or contaminants that might interfere with its proper functioning. Applying a regular lubrification routine on all moving parts can also reduce friction and ensure smooth operation. It’s important to follow the manufacturer’s guidelines for cleaning and maintenance to avoid damaging the device.

Additionally, storing stun batons in optimal conditions is vital. Keep them away from extreme temperatures, direct sunlight, and moisture. Using a protective case or pouch when not in use can also safeguard the equipment against physical damage and prevent any internal short circuits that might lead to misfires. Regular checks for wear and tear, especially on critical components like the trigger mechanism, will help identify potential issues before they result in unexpected malfunctions.

In conclusion, preventing stun gun misfires is paramount for effective and safe heavy-duty stun baton deployment in security applications. By understanding the mechanisms behind misfires, incorporating robust design features like advanced sensors and user protection measures, and maintaining equipment properly, professionals can ensure these powerful tools function as intended when needed most. Investing in high-quality, well-maintained heavy-duty stun batons for security is a vital step towards enhancing officer safety and public protection.